Posted: November 30, 2024

Photo: China Academy of Building Research

IEA SHC Task 69 on Solar Hot Water for 2030 brings together the expertise of solar water heating technology experts in Africa and Asia Pacific. Typical failure modes and relevant quality and testing methods were discussed in detail with Chinese industry representatives during a Solar Academy session in China in October 2024. The key outcome is a list of 12 failures and their impact on the performance of thermosiphon systems related to design, installation and operation. The photo above shows the international trainers from Task 69 together with the hosts from the Solareast Group in Lianyuangang, China, on the test field. The training session was an integral part of the two-day Sustainable Solar Building & Industry (SSBI) conference jointly organized by China Academy of Building Research and the Solareast Group, one of the world’s largest collector manufacturers.

“Even though thermosiphon systems have been around for a long time, they still suffer from key, unresolved issues in certain markets,” explained Prof. Robert Taylor, Co-Manager of Task 69. “Our Task 69 research group works to categorise these issues and think about ways to alleviate them through improved design, training of installers and through general best practices. In the end we need to ensure thermosiphon systems fit the needs of today’s customer.”

Prof Robert Taylor during the Solar Academy training session in Lianyuangang, China, in October 2024 Photo: China Academy of Building Research

Prof. Li Bojia from the Solar Energy Application Center of the China Academy of Building Research used the forum of an IEA SHC Solar Academy webinar in September to present the results of the discussions with solar heat experts, mainly from Southern Africa. The recording and the presentations of the webinar are available online (https://www.iea-shc.org/solar-academy/webinar/solar-thermosyphon-hot-water-systems)

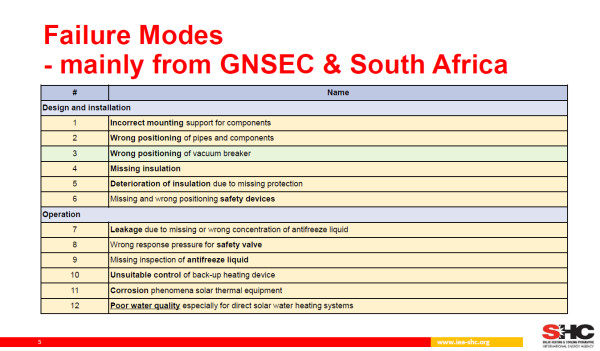

Of the 12 categorized failure modes that were identified, the first six are related to design and installation, while the second six relate to operation (see listing above). The first group is all about incorrect installation, wrong positioning of components and missing insulation. The second category includes problems with leakage, anti-freeze, unsuitable control and corrosion. The last failure is related to poor water quality, which has an acute impact on thermosiphon system performance, especially in the Southern African region.

All failure modes are described with text and illustrated with photos in a report titled “Solar Hot Water Failure Modes Analysis” which will be published in the first half of 2025 online. https://task69.iea-shc.org/publications

Photos of failure modes: The vacuum breaker is installed in the wrong way (left-hand photo), so there is no thermosiphon loop in place to prevent back flow out of the tank if there is not sufficient cold-water supply. Stress corrosion cracking manifests itself as intergranular and branching cracks (right photo).

Photos: Rudi Moschik / image from internet

The Task 69 team compiled some suggestions for improving the reliability and durability of thermosiphon systems:

- Standards and guidelines: better design & basic performance

- Testing and certification: product quality

- Training and qualification: incorrect installation & operation

- Smart detecting: future thoughts for operation

“Smart controllers for thermosiphon systems can help to avoid some of these failures and to achieve better-performing installations”, said Taylor during the webinar. “There are new electronic devices that can monitor, for example, the state of charge of the tank, check for impurities in the water or corrosion effects in the solar circuit”. Such devices are getting a lot cheaper and better these days and more connected with other household energy systems as well, according to Taylor.

“Quality products and regular maintenance are key factors for long-lasting systems”, emphasized Rudi Moschik. He is Senior Engineer at the Austrian Institute AEE INTEC with a decade of experience in training and site visits in Southern African countries. He presented photos of 20-year-old thermosiphon systems which have performed well over this long period because of proper maintenance.

Moschik is part of the implementation team of SOLTRAIN – the regional initiative on capacity building and demonstration of solar thermal systems in the Southern African region. The initiative has provided financial and technical support for the installation of over 700 best-practice installations, mostly with thermosiphon systems. Some of the systems are listed in an online overview: https://www.soltrain.org/systems/

Websites of organizations mentioned in this news article: