Posted: October 19, 2023

In a circular economy the efficient supply of carbon-free energy and the recovery of resources as well as the treatment of wastewater must go hand in hand. In the IEA SHC Task 62 on Solar Energy in Industrial Water & Wastewater Management more than 50 experts worked intensively together to identify new collector technologies and new applications in this field. In particular, they looked at separation technologies such as membrane distillation and photo-processes like photocatalysis in combination with solar process heat. Innovative solar collector concepts that integrate water treatment technology into the collector represent a leap forward in the collector industry. Sarah Meitz, a specialist for water and process technologies at the Austrian research institute AEE INTEC, was among the leading members of the Task 62 team. We spoke with her about the key findings of the four-year research collaboration.

Wastewater treatment and desalination are processes that require a lot of energy. They are currently still predominantly powered by electricity. What is the argument for powering these processes with solar thermal energy?

Meitz: The forecasts show that the global electricity consumption for wastewater collection and treatment will require over 40% more energy in 2040 compared to 2014. If electricity is the predominant energy source, this will increase the strain on the electrical energy power supply infrastructure. Therefore, concepts for wastewater treatment that counteract this trend are important. As an example, thermal separation technologies such as membrane distillation could play a major role, as their operating temperatures are below 100 °C – a perfect temperature range to be supplied by renewable technologies like solar thermal energy or waste heat. Another possibility is the direct use of photons for wastewater treatment in combination with fuel production (e.g. hydrogen) via photo processes like photocatalysis or photoelectron-chemistry.

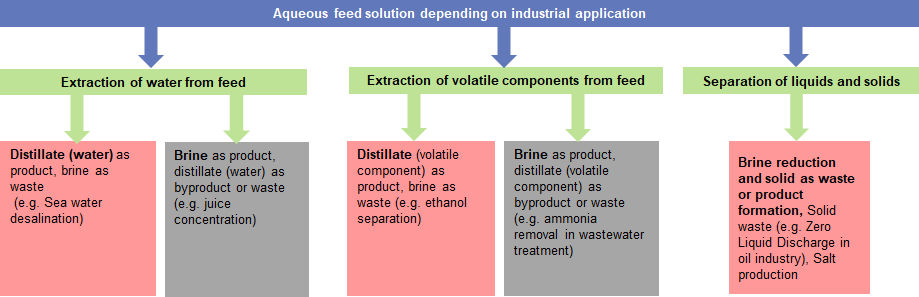

Matrix illustrating industrial processes and suitable water separation technologies.

Source: IEA SHC Task 62 / Fraunhofer ISE

The IEA SHC Task 62 team developed the matrix above. Can you explain its structure?

Meitz: Individual fields of application for separation technologies are described in detail in the literature, but with this matrix we wanted to create a general overview of application possibilities. We first identified the three major water treatment processes, which are water extraction, volatile extraction and concentration of liquids/solids (see green part of the matrix). For each of these major divisions we identified subdivisions (red/grey parts) and we named an industrial process as an example in brackets at the bottom of each box. The matrix has also been further detailed in terms of specific application areas in industry and occurring wastewater streams.

Who can use this matrix and how?

Meitz: This matrix is helpful for system integrators and providers of water-treatment solutions as well as end users from various industries. They can find possible applications for different industrial sectors. Explicitly mentioned examples in the matrix include: metal recovery in the plating industry, recovery of rinsing water or dye in the textile industry and fruit juice concentration in the food industry.

The matrix will be part of a report with the title "Industrial separation demands to be subjected to cutting-edge thermal technologies versus availability of different low-exergy heat sources" which will be available on the Task 62 website at the end of the year.

Membrane distillation was a key topic in the task, why?

Meitz: Firstly, in the task definition phase the community already showed great interest in the topic, especially as membrane distillation acted as a great example of a process being supplied with renewable energy sources. We also had many experts from the field of membrane distillation in the task, including the membrane module manufacturers Solarspring and TheVap from Germany and Aquastill BV from the Netherlands. We worked interactively with a mind map at task meetings to identify research and development needs in this area. This was a very valuable exchange between representatives from research and industry.

From the exchange of information within the task, we can summarize that membrane distillation technology is definitely available, but has so far only been used on a small scale. The visibility of the operational results from existing plants at different scales and for different applications should be increased. However, the task participants all agreed that there is a high potential for using solar thermal energy in membrane distillation.

What are the R&D needs in the field of membrane distillation?

Meitz: Further improvements in membrane technologies are necessary, particularly in terms of long-term stability and efficiency. Especially for membrane distillation, there is a high need for research to minimize fouling in organically loaded water streams. The problem here is that organic substances are deposited on the membrane surface and thereby lead to significant changes in the natural properties of the membrane.

Current R&D activities are primarily focused on studying scaling in laboratory-scale seawater treatment equipment using synthetic water. In addition, the processes are being depicted in simulation models. However, these studies now need to be extended to other complex wastewater streams in order to obtain a broader knowledge of the critical operating conditions for membrane distillation in industrial wastewater treatment and to develop suitable design tools.

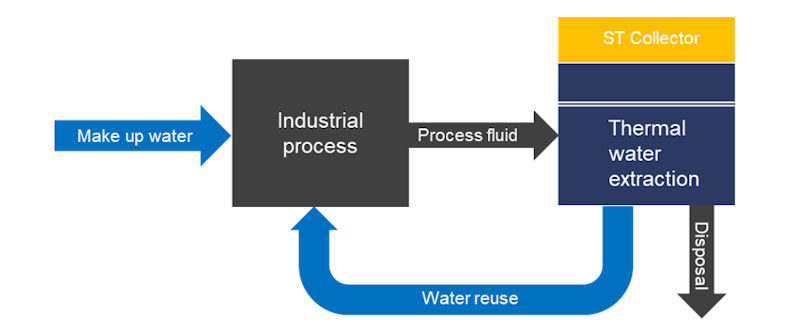

Block diagram of a water-treatment system with an integrated solar thermal heat supply.

Source: IEA SHC Task 62

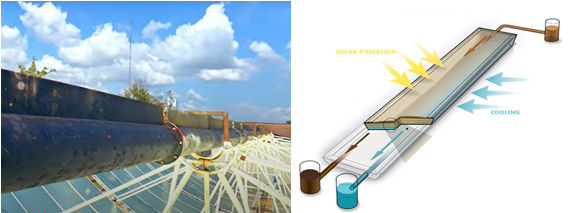

In the Task 62 Technology Position Paper you list several actions needed to increase the use of solar thermal energy for water treatment. One action item is that solar reactor concepts need to be developed in which solar supply and processes are merged in one collector. Which solar reactors are already available on the market?

Meitz: In general, two possible concepts for solar reactors are available: firstly, the use of solar thermal energy for wastewater treatment and secondly, using photons in photo-processes like photocatalysis. Systems in which the water-cleaning process takes place directly in the solar collector are still rare. Further, it would also be interesting to make use of solar photons and thermal energy in one collector concept – the amount of research that has been done on this topic is particularly low.

One existing exemplary concept represented within the task was developed by Solardew, located in the Netherlands. Solardew's concept consists of a solar collector combined with membrane distillation, which enables the production of drinking water from virtually any source of polluted, contaminated or saline water using solar radiation. The main sales markets are developing countries, emergency relief (e.g., natural disasters), military, etc.

Two prototypes using solar collector concepts for water treatment: from the company JWA Oilfield Supplies in Australia, called Flamingo (left), and from the company Solardew, situated in the Netherlands (right). Photo left - taken from a film: https://www.jwaoil.com/products/flamingo-water-treatment /

Photo right: Solardew

What lessons have you learned from the four years of task work that would be useful for manufacturers of innovative collector technologies who want to offer solutions in the field of water treatment?

Meitz: The work within IEA SHC Task 62 showed the great potential of solar energy in wastewater treatment. For the solar industry, opening new markets for existing collector concepts but also new innovative approaches are possible. Nevertheless, there is still a high need for further action to be taken.

The current obstacles to solar integration are complex systems, many components, losses along the supply chain, low efficiencies, and high system costs. The transition to an intensified and combined unit in the form of solar reactors represents a leap in innovation for industrial and municipal water treatment processes to overcome these limitations.

Websites of organizations mentioned in this news article: